Our machinery is designed for the production of high-end-components for aviation and industry. For example we manufacture high-tech Parts for a variety of Airplanes as well as roadworthy e mobile special vehicles up to small series for motorsport (from a production batch of one to about 100 vehicles)

State-of-the-art CNC-machines have a network connection to the CAD-CAM work stations . In this way, extreme accuracy and optimal workflow in the manufacturing process are guaranteed in an effective and highly efficient way.

We are:

- DIN ISO 9001 certified

- QSA-A Certified (certified company for aviation, aerospace and equipment industry)

- equipped with special tools for the machining of highly-resistant materials (for example titanium

alloy)

Services in the area of production:

- CAM-supported CNC manufacture on up to 6-axis milling centres for the machining of complex

- components (component dimension up to 1.800mm in length)

- Wire-eroding and sink erosion

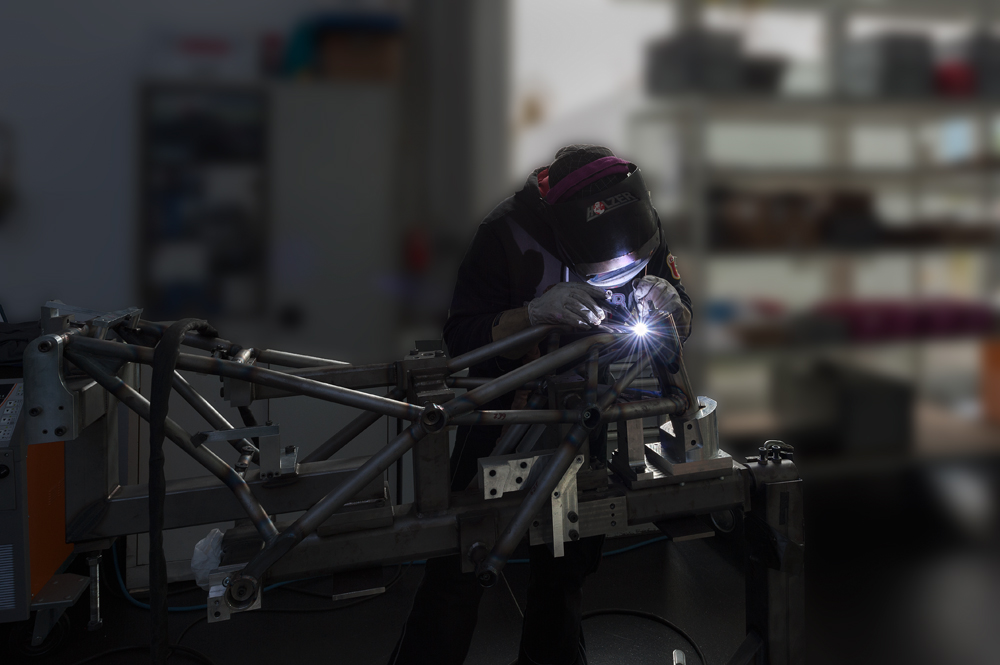

- High-precision welding

- DMSB certified manufacture and installation of rollover structures

- Own jig department, tooling shop and mould construction

- Permanent quality control on state-of-the-art measuring systems

- Measuring of shape and position tolerances

- Measuring of surface roughness

- Preparation of documentation

Services in the area of assembly:

- Preparation of vehicles ranging from prototypes to small series

- Vehicle preparation mounting plate 3,000x6,000mm with mobile gauge arm

- Assembly of components

- Mechanical component design